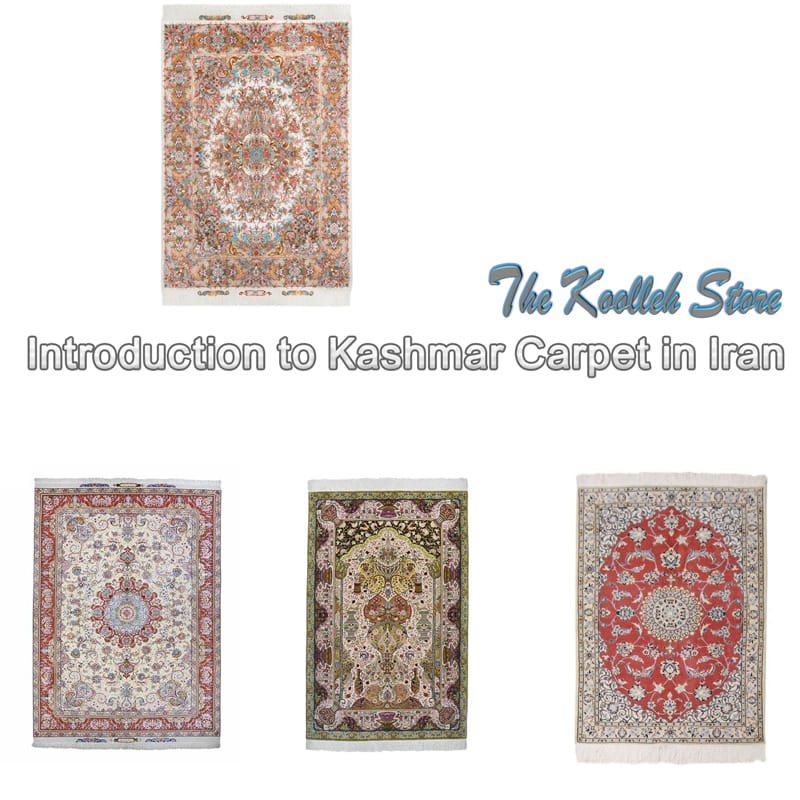

Introduction to Kashmar Carpet in Iran

At present, about 10 dyeing workshops in Kashmar provide an important part of raw materials for Kashmar carpet and its suburbs. . Although the use of herbal dyes is limited to component manufacturers, their numbers are very small and cannot be emphasized.

The type of varnish color used in Kashmiri carpets can be considered as one of the differentiated and perhaps recognizable textures of this area. This type of lacquer, which is known in other areas as lacquer glitter, has long been widely used in Kashmiri woven fabrics and is used in Kashan style carpets, both past and present.

The type of knot used in Kashmar rugs and its suburbs is Persian knot, but Turkish knot is also used sporadically. The bud of all Kashmiri rugs is done after the tissue finishes. Polishing workshops are also used for polishing and trimming knots after carpet finishes.

The owners of this area are often wooden and in recent years the use of iron or the use of iron in some parts of it has become common. Iran Carpet Company seems to be the largest user of iron ore in the region at present.

The carpeting of all Kashmar rugs is known as Turkish and on the rug. At present wool, as the main material of Kashmar rugs, together with the limited use of silk in Nain light carpets, constitute the raw materials used in Kashmar rugs. Another highlight in today’s Kashmiri carpets, especially the Naein style carpets, is the bleaching of wool coats before use.

In other words, all of the white cream used in the Naein carpets is dyed again with white paint before weaving, causing false and excessive white glitter on the carpet texture. The reason for this is not clear yet, and this is the first time we have approached this way, and despite repeated questions, there has been no convincing answer from the weavers and weavers.

Perhaps one of the reasons for this is the use of shoddy wools that dye them because of their lack of whiteness and one-handedness. However, this is a reason to reduce the quality and quality of the yarn used in the region. More than 70% of cotton yarns are supplied from Isfahan and the rest from Mashhad factories.

Leave A Comment

You must be logged in to post a comment.